WHAT IS ULTRAVIOLET DISINFECTION?

• A chemical free disinfection.

• Utilises an ultraviolet light emitting a 254nm wavelength to physically disarm microbiological contaminants.

• Does not alter the water’s chemistry – altering the taste and smell.

• Extremely effective means of protecting your water.

• Cost-effective technology.

• Protects against harmful microbiological contaminants including E-coli, giardia lamblia and cryptosporidium.

Low

power consumption

Easy

maintenance

Affordable

to install and maintain

Reliable

technology

What sectors?

• Anywhere that wants to protect their water.

• We supply to a huge range of residential, industrial & commercial sectors;

• Hospitality

• Food & Beverage Production

• Manufacturing

• and much more …

What is a typical process?

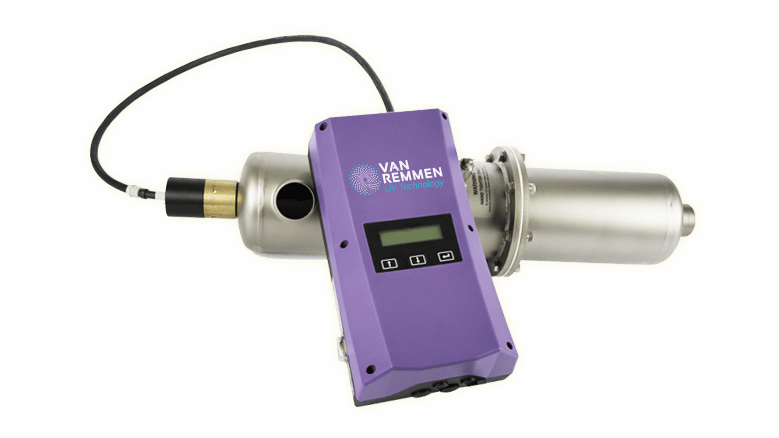

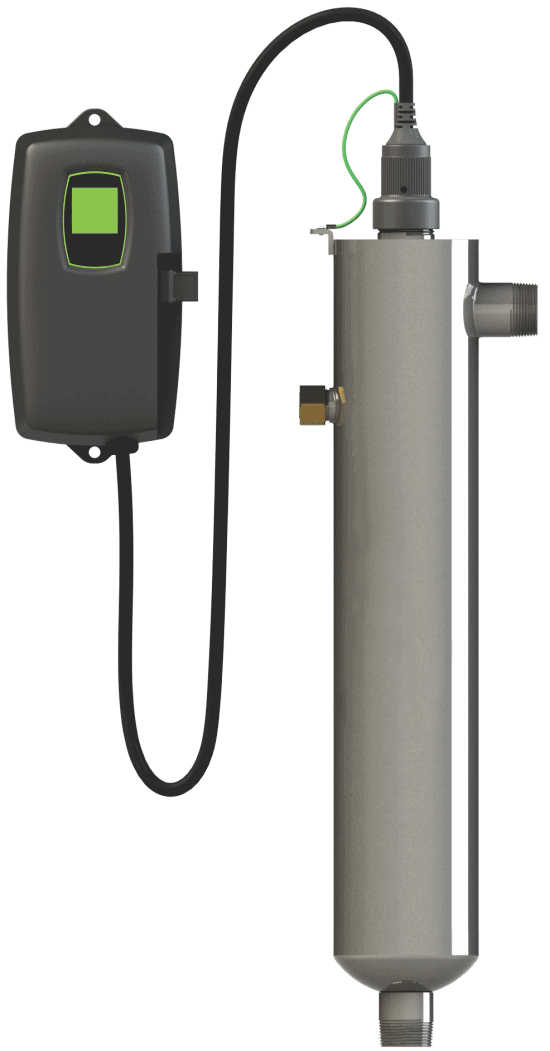

• Water enters the stainless steel UV chamber and comes into contact with a 30mJ/cm2 @ t10 95% ultraviolet light dosage.

• The light provides a dose that is able to change the genetics of the microbiological contaminant’s DNA.

• The dose results in a sterile, disinfected water supply.

• Quick process.

• UVs should always be sized larger than require to ensure an adequate dose of disinfection is applied.

Why Siren Water Treatment?

• Years of experience sizing ultraviolet disinfection systems.

• We offer supply, installation and commissioning.

• We provide reports upon completion stating exactly what has been done.

• Part of what we do is educating companies and share our knowledge and expertise.

FAQs

In short, yes. The UV system has to be sized larger than the flow rate that is being processed through the system to ensure that there is an adequate exposure time to the UV light. UV systems are able to handle high pressures, however we would recommend that you contact one of our technical advisors to discuss the most suitable solution for you.

dependent on your requirements yes, however it is recommended to install a 5µ filter before your UV to protect the delicate UV components and ensure masking doesn’t occur. Masking, also known as shadowing is the process where if particulates > 5µ pass through into the UV chamber then the microbiological contaminants could potentially pass through the system without coming into contact with the 254nm ultraviolet light; this results in potential bacteria and viruses passing to service.

To guarantee bacterial protection, it is recommended that lamps be changed once a year for a standard output lamp on an annual service.

UV disinfection is a reliable and economical method of removing microbiological contaminants such as bacteria and viruses. There are clear advantages to using UV disinfection:

• Physical disinfection

• No chemicals required

• Minimal power consumption

• Doesn’t alter the water chemistry as chemical disinfection does

• Minimal power consumption – cheap to run

• Environmentally friendly

• Reliable

• A worldwide recognised disinfection means

• Minimal maintenance required

• Automatic process